No records can be found for filling line clearance. No formal, in depth, and precise SOP for filling line clearance. Line clearance of filling room is conducted by filling line operators devoid of official paperwork or double-examining.

Staff want to comprehend the why and the implications In case the why is neglected. Moreover, corporations should really introduce stringent comprehensive risk assessments at every move of aseptic processing.

This agility in launching solutions don't just provides them a aggressive edge but in addition fosters more powerful relationships with prospects, in the long run resulting in higher levels of fulfillment.

Get the job done inside a confined, managed natural environment for extended periods of time, operating efficiently for a group member.

Clipster® is a single-use Answer for disconnecting tubing at any stage in the procedure even though preserving sterility.

IVEK offers cost-free in-depth Assessment to ascertain one of the most correct fluid handling technique to your application.

Filtered compressed air and granules of the plastic product conforming to your predetermined specification and recognized to generally be compatible Together with the merchandise to become crammed (usually polyethylene, more info polypropylene or polyethylene/polypropylene co-polymers) are equipped towards the here device.

I'm able to revoke my consent Anytime with effect for the longer term by sending an e-mail to unsubscribe@sartorius.com or by clicking about the "unsubscribe" backlink in e-mails I have been given.

The information of our Site is always readily available in English and partly in other languages. Pick your desired language and We are going to provide you with the material in that language, if available.

The assistance furnished by all course of action homeowners and supervisors is significantly appreciated for the precious responses and brainstorming classes provided by in defining threats inside the cleanroom entry and exit processes, glass bottle washing device operation, and glass filling process.

With this area, the drug product or service is particularly susceptible to opportunity sources of contamination; thus, the natural environment have to keep on being totally sterile.

I want to enroll in newsletters from Sartorius (Sartorius AG and its affiliated firms) based mostly of my own passions.

Clipster® is an individual-use Option for disconnecting tubing at any stage in the process even though sustaining sterility.

A comprehensive portfolio of ordinary and personalized tube sets for transfer, distribution or filling of in-approach fluids.

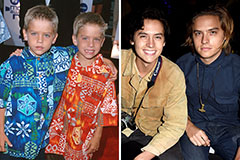

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Ross Bagley Then & Now!

Ross Bagley Then & Now! Katie Holmes Then & Now!

Katie Holmes Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!